NPE 2024

Maximum Performance: ILLIG presents an extensive thermoforming and packaging portfolio at NPE 2024

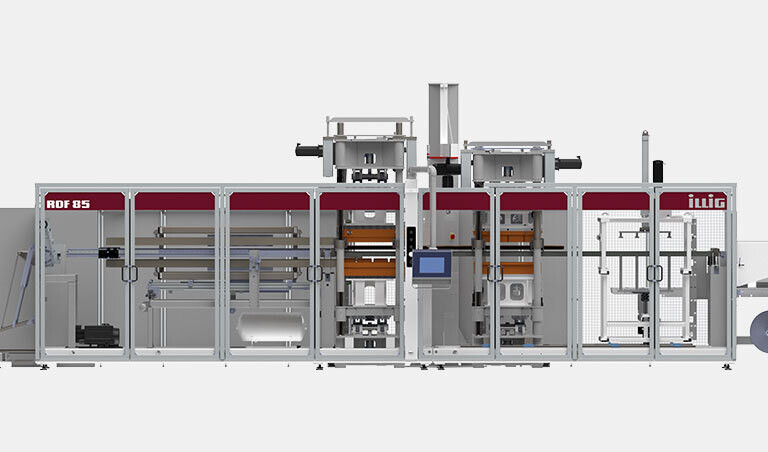

New RDF 85 XL thermoforming system with Sencorp 2500 tool compatibility

At the NPE Plastics Show from May 6 to 10 in Orlando, Florida, the German machine builder ILLIG will be presenting an extensive portfolio of thermoforming and packaging solutions. In addition to classic packaging solutions, such as cups, lids, capsules or clamshell packaging, this year's trade fair appearance will also focus on heavy gauge thermoformed parts, which are used in the automotive industry or for logistics solutions. ILLIG's latest product innovation is the RDF 85 XL thermoforming system, which has been developed to meet market requirements in North and Central America.

RDF 85 XL: Modular thermoforming system with Sencorp 2500 interface

The RDF 85 XL is an enlarged and reinforced version of the modular RDF 85 thermoforming system. For the first time, tools from the manufacturer Sencorp can be used in the XL version thanks to the open tool interface. The technology leader from Heilbronn thus offers its customers not only a cost-efficient and modern thermoforming system in proven ILLIG quality, but also a flexible solution for the future-proof operation of existing Sencorp 2500 tools.

The system openness of the RDF 85, i.e. the possibility of using competitor tools, has been extended with regard to the US market. The XL version will allow to run Sencorp 2500 tools without prior adaptation. In order to enable the use of the Sencorp tools available on the market, the forming area of the machine has been increased to 920 mm (36.2") in the production direction. The punching force has been increased to 80 tons. As is typical with Sencorp, the forming and punching tools are changed in a block. The tool change sequence of the ILLIG system has been newly developed for this: the steel rule die cutter is movable so that the tools can be lifted in and out as a block with a crane. The tools can then be pushed into the forming and punching stations via rail systems. Such a tool change can be carried out in around 30 minutes.

ILLIG offers fast stack handling and other end-of-line solutions to match the production line, which impresses with its high performance and optimum forming accuracy.

“With the RDF 85 XL, we have implemented current market requirements from North and Central America. For thermoforming companies with a stock of Sencorp tools, we now offer a cost-efficient and future-proof solution for utilizing their tools in a cutting-edge thermoforming system," says Erik Hemgesberg, VP Business Unit Thermoforming and Packaging Systems.

Performance meets Quality: RDM 76 Kb thermoforming system

Another trade fair highlight will be the RDM 76 Kb high-performance thermoforming system. The established machine line is known for maximum output and has recently been further optimized in terms of energy efficiency and ease of operation. Visitors will be able to experience the new control concept (HMI) on site and convince themselves of the product quality and performance of this high-end solution with a variety of RDM product samples.

Versatile packaging solutions

In the mobile packaging lab, ILLIG will be showing a variety of innovative packaging solutions that have been developed in collaboration with ILLIG customers and partners. The focus here is on plastic reduction, recyclability and the efficient use of energy and compressed air. ILLIG will also be presenting sustainable packaging solutions in the form of pulp/plastic or cardboard/plastic combinations.

Heavy gauge thermoforming: Sheet processing thermoforming systems for large-format automotive and logistics applications

ILLIG has two systems with forming areas from 600 x 500 mm to 3,000 x 2,000 mm, drawing depths of up to 800 mm in its portfolio: the UAF and UAg sheet processing thermoforming machines. The entirely newly developed sheet processing thermoforming machine UAF with its flexible clamping frames is the number-one choice when it comes to flexible production of small to medium batch sizes with frequent tool changes. Developed from scratch and introduced in 2023, the machine has an automatic sheet loading system and an integrated preheating and finish heating system that realizes shorter cycle times and guarantees an optimum forming process. The UAF is available in four sizes for all common sheet formats.

For this newly developed machine, special emphasis was placed on an energy-efficient design: servo motors, regenerative drives, preheating and an efficient heating system all add up to reduced energy consumption and therefore lower energy costs per formed part. A tool change on the UAF is possible in under 30 minutes. Forming tools made by market competitors can now be used, too. For post-processing, ILLIG offers various options and handling systems via partners. With the UAF, the German system supplier with its own toolmaking unit continues to pursue its path towards higher performance, enhanced sustainability and increased flexibility.

Furthermore ILLIG offers the UAg, a proven sheet processing thermoforming system. The UAg is known for very short cycle times and maximum output, and continues to set the benchmark here. Combining the UAg with fixed clamping frames enables the very highest final vacuum levels. The UAg series covers forming areas from 270 x 170 mm to 2,450 x 1,450 mm with drawing depths of up to 700 mm. This means it is particularly suitable for formed parts in large batch sizes. Automation via a sheet- or roll-loading unit is possible with all UAg machine types.

Most recently, ILLIG has worked with its customers to optimize the machine and process configuration of the UAg series in order to achieve maximum output. For example, considerably higher cycle times can be achieved by using a third heating unit. With an investment of 25% of the total cost for this extension, it is possible to increase the performance of the machine by up to 80%.

Tool making and service on site

ILLIG underlines its position as a full-service provider by presenting its comprehensive range of services covering the entire machine life cycle as well as its own expertise and worldwide partners in tool making.

Downloads

About ILLIG

ILLIG is a leading global supplier of thermoforming and packaging systems for the production of sustainable and recyclable plastic and fiber-based packaging. The company's services include the development, design, assembly and commissioning of complex production lines and tools, as well as brand-specific retrofit solutions. Packaging development is at the heart of the business: the company works with customers to develop resource-efficient and sustainable solutions and supports packaging converters in design and production. For more than 75 years, customers have valued the technology company as a reliable and globally active partner. ILLIG stands for innovative technology, top quality and comprehensive global service.

Further information:

Marketing & Communications

Tel.: +49 7131 505-0

E-Mail: media@illig.com

Note: Terms marked with ® are registered and protected trademarks of ILLIG. Pictures: ILLIG