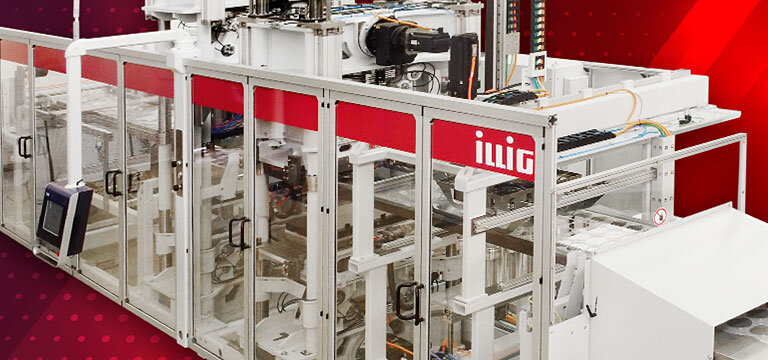

The new LEADER in

packaging systems

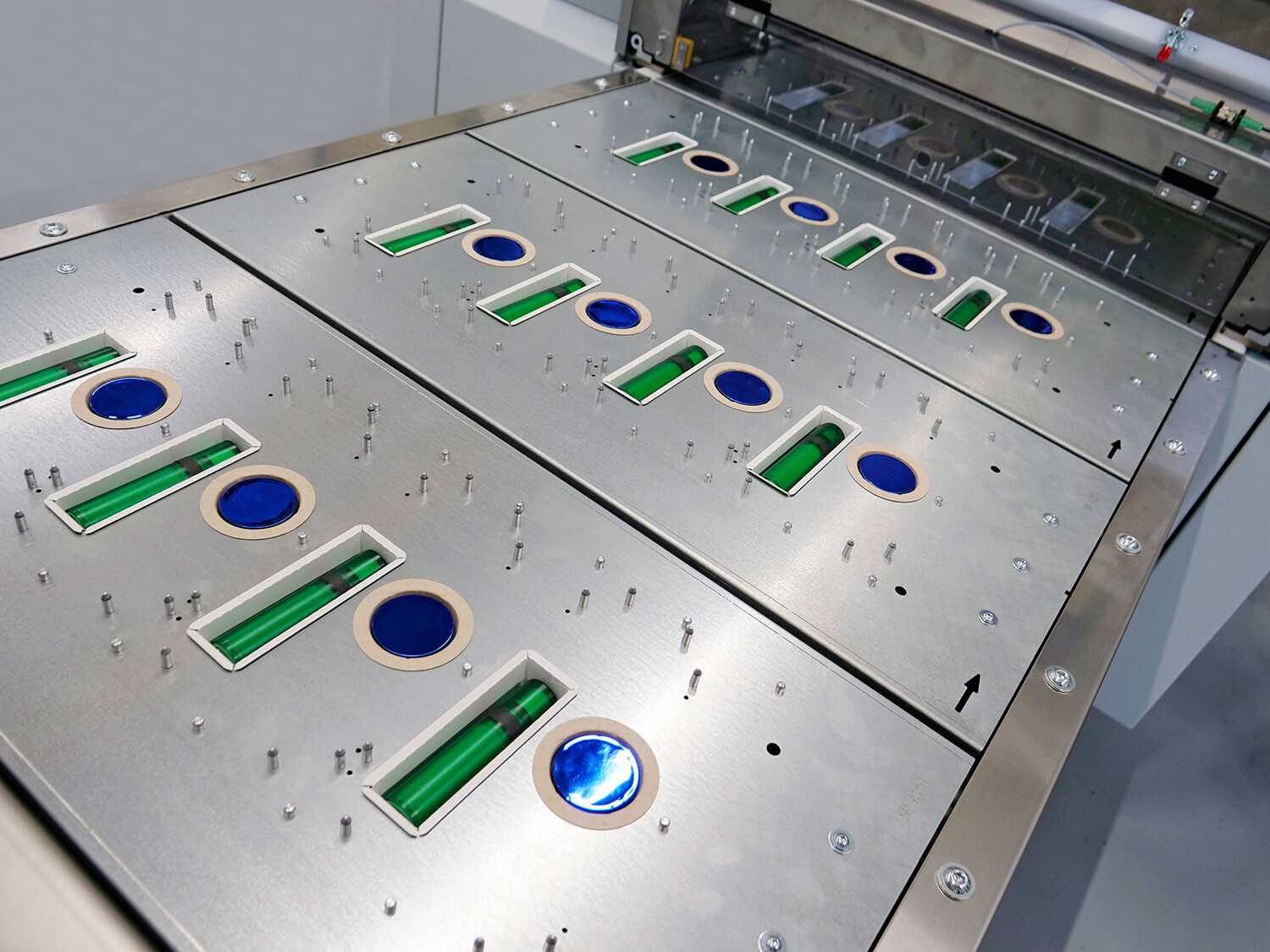

ILLIG continues its successful machine generation of the HSU series

(Hot Seal Unit) and sets new standards with the HSU 650 packaging machine for sustainable packaging.

Thus, the HSU 650 is another building block of ILLIG's "paperization" strategy in the "non-food" sector and contributes to the switch to paper and pulp.

HSU 650

Technical data

-

Forming Area (mm)

650x300 -

Sealing Area (mm)

650x300 -

Cycle speed

up to 20 cpm -

Depth of draw (mm)

up to 80 -

Sealing force (t)

up to 6 tons -

Sealing force (t)

up to 6 tons